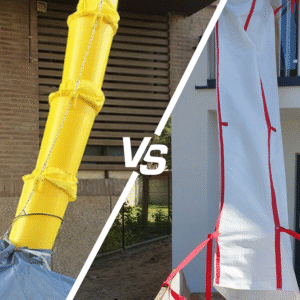

Construction chute vs flexible sleeve: which solution is worth choosing?

Systems for transporting debris from higher floors are an indispensable part of renovation and demolition work. In practice, we encounter two main solutions: segmented construction chute made of PE and a flexible sleeve made of fabric or flexible plastic.

While both are designed to streamline operations and improve safety, they differ in many aspects, from the way they are installed to their durability and cost of operation.

In this article, we pretive comparison of the two systems, based on the experience of construction teams, rental companies and manufacturers.

What are debris chutes and what are they used for?

Construction debris chutes are devices that enable safe and controlled discharge of construction waste (mainly debris) from the upper floors without the need to carry them down the stairs or elevator by hand. They are indispensable at:

- demolition work,

- Demolition of walls, ceilings and plaster,

- Insulation and installation replacement,

- general renovations,

- Projects with limited access to the first floor or maneuvering area.

Debris chutes significantly increase work efficiency, reduce risk of injury i reduce dust, which is important not only for comfort, but also for applicable health and safety regulations and environmental protection.

Two basic types of debris chutes dominate the market:

Segmental (modular) chutes – rigid, made of PE plastic

This is the most common system in the construction and rental industries. It consists of individual modules of about 1 m in length, which are connected to form a column.

- High durability – for repeated use for at least several years

- Can be easily scaled – you adjust the length to the height of the building.

They are best suited for heights of 5-30 m and working with heavy debris (concrete, brick, steel).

Our segmented chutes are manufactured from DOWLEX™ 2629.10 EU – a specialized, impact- and abrasion-resistant linear polyethylene (LLDPE).

Each segment is 1.04 m long, which allows precise planning of the configuration.

The system is designed for intensive use, including in equipment rental shops where durability and trouble-free operation are a priority.

Thanks to a rigid structure and a well-thought-out connection system, the chutes remain fully stable even when fully loaded and in harsh weather conditions.

TECHNICAL SPECIFICATIONS OF DROMADER CHUTES

Flexible sleeves – made of fabric or PVC plastic

This is a cheaper and lighter alternative used mainly for short-term, minor renovations. The sleeve is hung from above, such as from a balcony or scaffolding.

Characteristics:

- Quick installation (several minutes).

- Less resistant to damage (for example, with sharp debris).

- Recommended mainly for light work (e.g., plaster, Styrofoam, fine debris without reinforcement).

- It does not require an elaborate supporting structure.

Worth knowing:

Sleeves can be a good solution for individuals doing a single renovation, but are not recommended for intensive work or tall buildings.

Durability and resilience – a comparison of two solutions

Segment chute

(modular PE)

Elastic sleeve

(textile-PVC)

- suitable for repeated use, with chutes of good quality durability is for years

- Resistant to mechanical damage (impact, abrasion),

- You can further protect the center of the chute with metal inserts,

- Handles debris of a larger fraction (brick, concrete, screws) well,

- lifespan of a minimum of several years, even with intensive use (with chutes of good quality)

- More prone to abrasion and tearing (the sleeve is made of elastic material)

- may be damaged when disposing of debris that contains sharp edges

- Limited weather and UV resistance,

- recommended for light demolition work or occasional use (use between 1 and 3 times)

- ideal for projects with limited first floor or yard access and when low purchase cost is important

Assembly and preparation time – comparison

Segment chute

(modular PE)

Segment chute

(modular PE)

- Installation time: from 30 minutes for 2-3 floors) to as much as 1-2 hours for heights of 20 m and more.

- Manning required: a minimum of 2 people, although with crane work it is possible to reduce the time and commitment of the team.

- Installation safety: the segmented system provides high stability and axial rigidity – reducing the risk of accidental bending or damage during installation.

- In practice: although the installation time is longer, for jobs lasting more than 2-3 days, the benefits of the system’s durability and rigidity outweigh the time investment.

- Assembly time: Between 20 – 45 minutes, depending on the length of the sleeve and the availability of the hanging point.

- Manning required: installation by 1 person is possible – an important advantage when working with limited personnel resources. The easiest and fastest way is to do the installation in two people.

- Unrolled from the top: the sleeve is lifted up (e.g., from a scaffolding or balcony) and then unrolled down – usually in one piece

- This system is dedicated primarily to temporary works or minor renovations, where time, ease of installation and low cost are crucial.

Every solution has its recipient – which type of chute to choose?

The segmented chute (PE segments) will work well in:

- Construction equipment rental companies need a durable solution that will rent repeatedly and last a long time

- Repair and demolition companies regularly dump heavy debris and sharp-edged items,

- Development companies and general contractors, conducting work at many large heights (5 – 30 m and more) and on many construction sites

- During demolition work, which generally requires reliability and repeated installation in different locations

The segmented chute (PE segments) will work well in:

- A private investor or small contractor plans a one-time renovation and accepts that the sleeve will last, briefly that is, between 1 and 2-3 uses

- What matters is the low initial cost, quick assembly and easy disassembly (assembly between 30 – 60 minutes, in one or two people)

- It’s about single, small jobs – such as dropping a light fraction of debris from an attic, balcony or 2-3 stories up to a few meters high

- The design requires mobility – the sleeve can be easily packed and stored in a small space

Summary

Both systems have their place in the industry: segmented PE chutes give unparalleled durability, safety and full compliance with health and safety standards for multi-story projects.

Flexible sleeves can perform well in short, small-scale renovations where low start-up costs and short installation times are key.

We, as a manufacturer of debris chutes from the Dromader series®, which are made of high-quality, certified polyethylene DOWLEXTM 2629.10 EU- is the solution we recommend for most professional applications. The flexible sleeve also happens to be a good alternative for small, one-off jobs. The flexible sleeve is especially recommended for private investors who are organizing a renovation and want to get rid of debris from the renovated building or apartment at a low cost.

If you need professional advice or a quick quote for a segmented chute, please contact us – we will. we will respond within a maximum of 24 hours and help you configure a solution perfectly suited to your project.

Contact us at your convenience:

Would you like a personalized quote?

Our sales consultants will prepare a quote tailored to your project.

Do you have a technical question?

Our specialists are happy to advise on installation, durability and best practices.

Are you interested in distribution cooperation?

We are open to building relationships with partners in Poland and around the world.